The machine is meticulously fabricated from high-quality mild steel, with a design that ensures exceptional robustness and mechanical strength, making it capable of withstanding the demanding requirements of shock testing. The robust construction guarantees that the machine remains rigid throughout the testing process, maintaining accuracy and consistency in results. The shock pulses are generated using compressed air, which forces the platform to impact against elastomer pads (Half-Sine Programmer Pads) placed strategically between the platform and the anvil in the impact area. These elastomer pads are specially designed to produce half-sine pulses, providing controlled and accurate shock profiles. Additionally, lead pellets are strategically positioned on the platform to generate saw-tooth pulses, while pneumatic cylinders are used to create square pulses. The combination of these different pulse-generating mechanisms offers a comprehensive range of testing possibilities. The desired shock acceleration levels are achieved by adjusting two key parameters: the drop height of the platform and the air pressure used in the system.

The platform’s lifting mechanism is controlled by precision pneumatic cylinders, which are responsible for elevating the platform to the required drop height. This drop height directly correlates to the acceleration level needed for the test. By adjusting the lift, the system can replicate a wide range of shock intensities, making it suitable for testing components under varying conditions. One critical challenge in shock testing is the occurrence of secondary shocks, which result from the rebound action of the platform after impact. These secondary shocks are typically unwanted and are not acceptable in most industry standards. To address this, the machine is equipped with fail-safe brakes, which serve as rebound brakes to absorb any unwanted rebound energy. These brakes also function as quick-release devices, ensuring that secondary and tertiary shocks are eliminated, maintaining the integrity of the test.

The shock test machine is isolated from the ground using heavy-duty shock absorbers and shockers. This isolation system prevents external vibrations from interfering with the shock testing process, ensuring that the test conditions remain uncontaminated by external influences. By minimizing ground interference, the machine delivers more accurate and consistent test results, making it ideal for high-precision applications in industries such as aerospace, automotive, electronics, and defense.

Pneumatic Shock Test Machine 500 Kg. Payload Capacity

Pneumatic Shock Test Machine 500 Kg. Payload Capacity

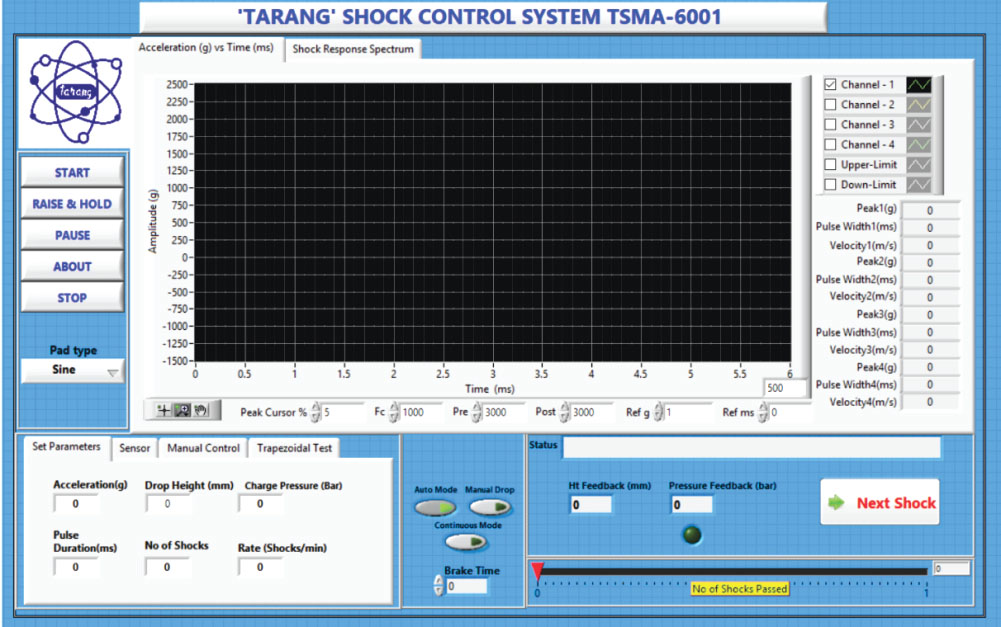

Supporting the shock test machine is a state-of-the-art, PC-based intelligent instrumentation system, which plays a critical role in controlling, monitoring, and analyzing the shock test waveforms. This advanced system is equipped with four channels to monitor shock pulses in real-time, providing detailed data on the performance of the test object. For more complex testing scenarios, the system offers the flexibility to expand up to 16 channels, allowing for a broader and more in-depth analysis of the shock test results. This system also provides powerful analysis tools that enable users to review, interpret, and make adjustments based on the acquired data, ensuring the highest level of accuracy in the testing process.

In addition to real-time monitoring and control, the intelligent instrumentation system offers advanced features such as automated calibration, fault detection, and data logging. This ensures that the shock test process is efficient, repeatable, and reliable, providing valuable insights for performance validation, research, and product development. Whether used for routine quality control, research, or development, this shock test machine and its supporting system provide a highly effective solution for assessing the durability and resilience of components exposed to shock forces.

| Advantages for you |

Key features |

| Customizable Reliable Solutions |

|

| Efficient performance |

|

| User Friendly |

|

Pneumatic Shock Test Machine 1000 Kg. Payload Capacity

Pneumatic Shock Test Machine 1000 Kg. Payload Capacity

Pneumatic Shock Test Machine standard models

| Model |

TSTS - 4040 |

TSTS - 6060 |

TSTS - 7575 |

TSTS - 1005 |

TSTS - 1010 |

| Table Size |

400 x 400 mm |

600 x 600 mm |

750 x 750 mm |

1000 x 1000 mm |

1000 x 1000 mm |

| Payload Capacity |

100 Kg |

200 Kg |

300 Kg |

500 Kg |

1000 Kg |

| Payload Height |

unlimited |

unlimited |

unlimited |

unlimited |

unlimited |

| Max Payload Size |

400 x 400 mm |

600 x 600 mm |

750 x 750 mm |

1000 x 1000 mm |

1000 x 1000 mm |

| Insert Pattern |

50 x 50 mm Matrix |

100 x 100 mm Matrix |

100 x 100 mm Matrix |

100 x 100 mm Matrix |

100 x 100 mm Matrix |

| Stroke Length (Max) |

400 mm |

300 mm |

350 mm |

350 mm |

450 mm |

| Velocity Change No load |

7.7 m/s |

7 m/s |

7 m/s |

10 m/s |

15 m/s |

| Velocity Change Full Load |

5.1 m/s |

5 m/s |

5 m/s |

8 m/s |

8 m/s |

| Standard Test* |

3000'g'-0.3'ms'

1500'g'-0.5'ms'

100'g'-6'ms'

50'g'-11'ms'

20'g' – 11'ms'

30'g' – 20'ms'

40'g' – 6'ms'

50'g' – 18'ms'

50'g' – 18'ms'

75'g' – 11'ms'

100'g' – 6'ms'

150'g' – 3'ms'

175'g' – 3'ms'

200'g' – 3'ms'

|

| Tests with Shock Amplifier (Optional) |

30,000 'g' with 1 Kg payload

10,000 'g' with 5 Kg payload

5,000 'g' with 10 Kg payload

|

| Pulse Shape |

Half Sine

Optional - Sawtooth / Square wave / Trapezoidal Waveform |

| Shock Rate |

1-8 shocks/min |

1-8 shocks/min |

1-8 shocks/min |

1-6 shocks/min |

1-5 shocks/min |

| Max Deviation of

specimen from

table centre |

30 mm |

30 mm |

30 mm |

30 mm |

30 mm |

| Machine

Mass |

4200 kg |

5000 kg |

6500 kg |

9500 kg |

19500 kg |

| Dimensions

(mm) |

1000*1000*1400 |

1200*1200*1500 |

1400*1400*1600 |

1600*1600*1700 |

2500*3000*2000 |

| Utilities required |

8 -1D bar compressed air (1-2 m3/minl , earthing) |

| Safety Interlocks |

Mains Input Over

& Under Voltage, Phase drop, programmer pad change

protection, over travel, Fail safe brake |

* Higher 'g' at lower 'ms ' and lower 'g' at higher 'ms' ; Various other bump tests canbe conducted other than the ones listed above

** Total dynamic height will increase after mounting test unit on platform and lifting for about 500 mm

Note : Customized solutions are available

Specifications are subject to change without notice. It is the responsibility of the product user

to determine the suitability of this product for a specific application.

PC Based Instrumentation System

The PC-based instrumentation system is designed to provide seamless control, real-time monitoring, and advanced waveform analysis capabilities, making it a highly efficient tool for shock testing. The system's interface is user-friendly, allowing operators to easily manage and monitor the test parameters, while also offering quick access to important data. It incorporates a range of safety interlocks, which are crucial for ensuring the safe operation of the machine and preventing any potential mishaps during testing. These safety features work in tandem with the control system to create a secure and reliable testing environment.

Once a test is completed, the system allows users to easily view and print detailed test reports, which contain all relevant data and findings. This makes it simple to track results, analyze performance, and maintain records for future reference or compliance purposes. Furthermore, the system is equipped with specialized Shock Analysis Software that is specifically designed for the analysis of the waveforms generated during the shock test. This software enables detailed interpretation of the test data, providing a deeper understanding of the shock responses and ensuring the accuracy of the results.

Screenshot of Shock Test Machine control and monitoring system

Screenshot of Shock Test Machine control and monitoring system

In addition to basic waveform analysis, the software also includes advanced features for performing Shock Response Spectrum (SRS) Analysis. This capability allows users to assess the impact of shock pulses on the test specimen, providing valuable insights into how different frequencies and accelerations affect the performance and durability of the tested components. With this combination of real-time control, comprehensive analysis tools, and user-friendly operation, the PC-based instrumentation system enhances the overall testing process, making it a powerful solution for applications requiring high precision and reliability in shock testing.

Download Product Catalogue